CVW-2512

# Enhancing Quality Control with Small Package Production Line Checkweighers

In the fast-paced world of manufacturing and packaging, precision and efficiency are paramount. Small package production lines, in particular, demand meticulous attention to detail to ensure that every product meets the specified weight requirements. Checkweighers play a crucial role in this process, serving as the last line of defense before products reach consumers. This comprehensive product introduction delves into the significance, features, applications, and benefits of small package production line checkweighers, shedding light on their pivotal role in elevating quality control standards.

## I. Introduction

### A. Definition and Purpose

A small package production line checkweigher is a sophisticated weighing system integrated into the production line to verify the weight of individual products. It operates in real-time, allowing manufacturers to identify and address any deviations from the target weight promptly. The primary purpose of checkweighers is to ensure the quality and consistency of packaged goods, meeting regulatory requirements and customer expectations.

### B. Significance in Production Lines

1. **Quality Assurance:** Checkweighers act as a final quality checkpoint, preventing underweight or overweight products from reaching consumers. This is vital for compliance with industry regulations and maintaining brand reputation.

2. **Efficiency Enhancement:** By automating the weighing process, checkweighers contribute to the overall efficiency of production lines. They operate seamlessly within high-speed packaging environments, reducing the need for manual inspections.

3. **Data Collection and Analysis:** Modern checkweighers are equipped with advanced technology that enables the collection and analysis of weight-related data. Manufacturers can gain valuable insights into production trends, identify areas for improvement, and enhance overall process efficiency.

## II. Features of Small Package Production Line Checkweighers

### A. Compact Design

Small package production line checkweighers are specifically engineered with a compact footprint to seamlessly integrate into limited space environments. Their design ensures minimal disruption to the production flow while maximizing efficiency.

### B. High-Speed Operation

These checkweighers are optimized for high-speed production lines, where products move rapidly through the packaging process. Their ability to weigh items swiftly ensures minimal impact on production timelines.

### C. Precision Weighing Technology

Utilizing advanced load cell technology, small package checkweighers offer precise and accurate weight measurements. This technology allows for the detection of even minor weight variations, ensuring stringent quality control.

### D. User-Friendly Interface

Modern checkweighers feature user-friendly interfaces, often equipped with touchscreens for intuitive operation. This simplifies setup, calibration, and monitoring, reducing the learning curve for operators.

### E. Customizable Settings

To accommodate a diverse range of products, small package checkweighers come with customizable settings. Manufacturers can easily adjust parameters such as target weight, acceptable weight variation, and rejection criteria.

### F. Integration with Other Systems

Seamless integration with existing production line equipment is a key feature of small package checkweighers. They can be linked to labeling systems, reject mechanisms, and data management systems for comprehensive automation.

## III. Applications of Small Package Production Line Checkweighers

### A. Food and Beverage Industry

Small package checkweighers play a critical role in the food and beverage industry, where accurate portioning is essential. They are employed in the weighing of packaged snacks, beverages, condiments, and other consumables.

### B. Pharmaceutical Sector

In pharmaceutical manufacturing, precision is non-negotiable. Checkweighers ensure that medication packaging adheres to strict weight specifications, meeting regulatory requirements and ensuring patient safety.

### C. Cosmetics and Personal Care

In the cosmetics and personal care industry, small package checkweighers contribute to consistent product quality. They verify the weight of items such as lotions, creams, and beauty products.

### D. Electronics and Components

Manufacturers of small electronic components benefit from checkweighers to verify the weight of individual items before packaging. This is crucial for product functionality and compliance.

## IV. Benefits of Small Package Production Line Checkweighers

### A. Regulatory Compliance

Meeting regulatory standards is paramount in various industries. Small package checkweighers aid manufacturers in complying with weight-related regulations, avoiding legal issues and penalties.

### B. Cost Reduction

By automating the weighing process, manufacturers can reduce labor costs associated with manual inspections. Checkweighers operate efficiently 24/7, ensuring consistent quality without the need for constant human oversight.

### C. Increased Productivity

The high-speed operation of small package checkweighers contributes to increased productivity on the production line. Swift and accurate weight verification means fewer disruptions and faster throughput.

### D. Brand Protection

Consistency in product weight and quality is integral to brand protection. Checkweighers prevent the distribution of underweight or overweight products, safeguarding the brand's reputation and customer trust.

### E. Data-Driven Decision-Making

The data collected by checkweighers provide manufacturers with valuable insights. Analyzing this data enables informed decision-making, process optimization, and continuous improvement in production efficiency.

## V. Future Trends in Small Package Checkweighers

### A. Integration with Industry 4.0

The integration of small package checkweighers with Industry 4.0 principles is a growing trend. This involves connectivity, data exchange, and automation to

**Checkweigher Features for Enhanced Operational Efficiency:**

1. **Operator Efficiency:** Streamline operations with clear and intuitive inputs for effortless use by operators.

2. **Easy Menu Navigation:** Simplify the user experience with easy menu navigation, facilitating quick and intuitive interactions.

3. **Extensive Parameter Storage:** Store up to 2000 product recipe parameters for versatile and efficient production management.

4. **Network Communication and USB Ports:** Enjoy seamless connectivity with standard network communication and USB ports, enhancing data transfer and accessibility.

5. **Information at-a-Glance:** Access production data, statistical records, and historical graphs at a glance for informed decision-making.

6. **Precision Checkweighing:** Achieve low-capacity checkweighing with sensitivity to < 1 gram, ensuring accuracy in weighing small products.

7. **High-Capacity Checkweighing:** Handle products weighing hundreds of pounds with high-capacity checkweighing capabilities.

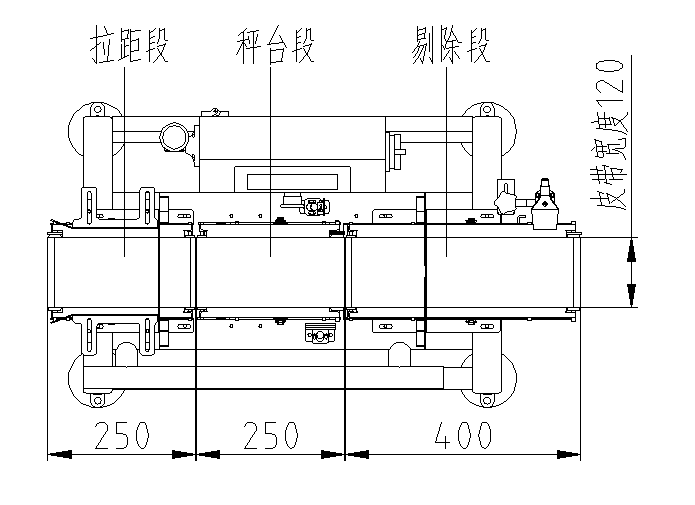

8. **Three Conveyor Design:** Benefit from a three-conveyor design comprising in-feed conveyor, conveyor scale, and exit conveyor for a comprehensive production line setup.

9. **Single or Multiple Lanes:** Opt for a single or multiple lane configuration to accommodate various throughput requirements, handling hundreds of pieces per minute.

These features collectively contribute to an efficient, user-friendly, and versatile checkweighing system, ensuring accuracy and productivity in diverse production scenarios.

The model CVW-2512 is a compact universal application small size checkweigher with high accurate

Throughput | Max180 ppm |

Belt speed | 20-60m/min |

Weighing Range | ≤200g |

Suitable Product Dimension | ≤100mm(L)*100mm(W) |

Weighting section | 250mm(L)*120mm(W) |

Transport Height | 550 mm - 1,100 mm (± 50 mm)Customized |

Industry | Food; Other |

Mini resolution | 0.01g(10mg) |

Accuracy | ±0.05g(50mg)~±0.1g(100mg) |

Production Environment | Temperature: 0℃~40℃,Humidity:30%~95% |

Operation language | English /Spanish/Russian |

Customization Options | Bespoke handling; OEM |

Approval | Weights & measures design approval for official verification (MID certifiable) If needed |